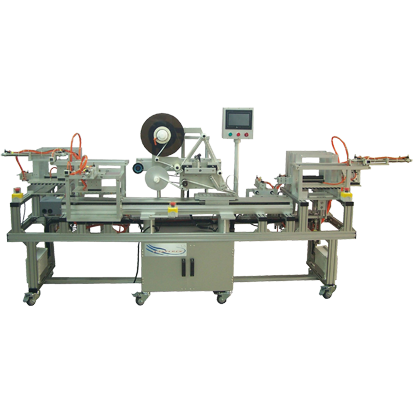

CCD-300 high precision automatic alignment labeling machine

Applicable scope:

Specially used in labeling various kinds of products that needed high precision label alignment.

Features:

1.Quality and aesthetic machine design in stainless steel and anodized aluminum alloy

materials.

2.The 1200 x 800 x 1900mm (L x W x H) clean booth uses FFU-MT18P ULPA filter with a filtering

effect of 0.1μm 99.999%.

3.EasyView color HMI touch-screen operation.

4.CCD camera will output the label deviation value, and the X- and Y-axis moving tables will

correct and align the labels automatically.

5.Label driving in Japanese-made Yaskawa servo motor and Keyance sensors.

6.X- and Y-axis moving tables driving in Japanese-made Yaskawa servo motors.

7.Panasonic PV series of CCD camera from Japan is used to detect the deviation value of labels

and products effectively.

8.Labeling accuracy of front, rear, left and right of labels is ±0.1mm ~ ±0.15mm.

9.Labeling speed: 5 ~ 8 cycles/min.

10.Labeling position, height and angle can be adjusted with a hand wheel.

11. Automatic machine shutdown when there is no label stock (optional).

| Machine dimensions | 1500 x 850 x 2000mm (L x W x H) |

| Machine weight | 250 kg |

| 滑台規格 | B130-P20 x 20-1200 |

| Maximum labeling size | 250 x 190mm (L x W) |

| Label roll size | Max. outer ø 310mm, paper core inner ø 76mm |

| Power rating | Single-phase 220V 50/60HZ |

| Dry compressed air | 6~8kg/cm2 |