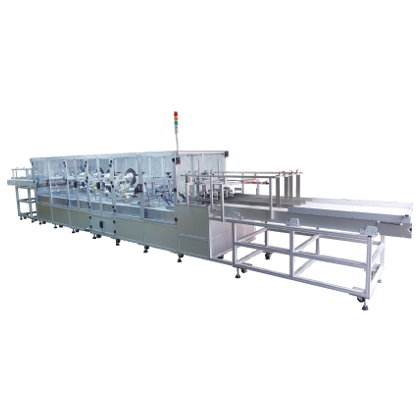

PML-340 High Speed In-line Egg / Fruit Clamshell Upwards Labeling Machine

Applicable scope:

Labeling on continuous of plastic pressure thermoformed fruit containers and Blister Trays。

Features:

1.High Quality and aesthetic machine design in stainless steel and anodized aluminum alloy materials。

2.EASYVIEW 10 inch Color Human Interface Touch Screen operation。

3.Labeling、Conveyor machine driving by Japanese Made Yaskawa Servo Motor。

4.Mitsubishi Programmable PLC Control System and deployed with Sick Photo Sensor made in Germany。

5.High speed Robotic Arm With 4 Grippers continuous feeding product mechanism to improve productivity。

6.4 labeling heads and hardware construction are controlled individually,enhancing labeling on blister tray with military

precision。

7.Automatic continuous collecting fixed quantity of products mechanism run and controlled by servo system。

8.Labeling Accuracy : ± 2 mm。

9.Labeling Speed :200~240 PCS / Min。

10.Labeling position、height、angle all can be adjusted by hand-wheel。

| Machine dimensions | (L)9400*(W)1200*(H)1800(m/m) |

| Machine weight | 2000kg |

| Product Size : | Max. : (L) 300*(W) 400 (m/m),Min. : (L) 120*(W) 120 (m/m) |

| Maximum labeling size | (L) 200*(W) 120 (m/m) |

| Label roll size | Max. Outer ø 300mm, Paper Core Inner ø 76mm |

| Power rating | 3φ、220V、5000W |

| Dry compressed air | 6kg/cm² |